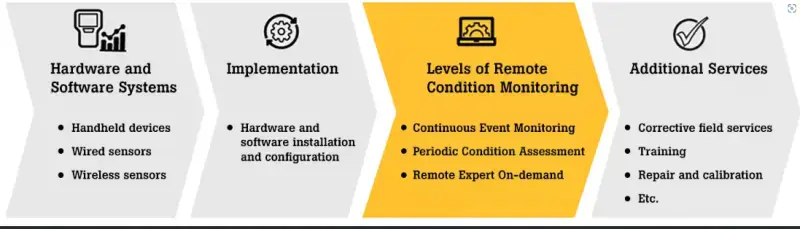

We offer end-to-end Remote Condition Monitoring solutions

Remote Condition Monitoring services, hardware & software

In today’s increasingly connected world, maintenance teams want to manage their assets with data-driven decisions — and the flexibility to do this remotely. But many organizations struggle with starting up, sustaining, or expanding their remote condition monitoring (Remote CM) programs due to a lack of in-house expertise, time, resources, and the right combination of solutions.

Fluke Reliability’s Remote Condition Monitoring service can be the critical difference between success or failure.

Fluke Reliability and Pruftechnik, part of the Fluke Reliability family, are home to some of the world’s top condition monitoring and vibration experts. Our global team can help you tackle challenges from start to finish. From implementation, configuration, reporting, analysis, diagnosis, vibration training and even corrective services, we can create custom solutions for your needs.

Speak to an expert

Lack a total solution for each stage of reliability journey

Lack expertise in PdM asset criticality, implementation

Lack data analytics experts to recommend actions

Early detection of machine-related issues

Improved maintenance planning

Prevent unscheduled and costly downtime

Extend equipment lifespan

Reduced maintenance & production costs

Full suite of hardware and software options

Decades of industry experience: More than 50 CATIII and CATIV experts

Breadth of Services: From corrective field services, training to technical support

Flexible, tailor-made solutions for customers’ needs

Training

We offer alignment, vibration & balancing, ultrasound, and reliability training.

FIND A COURSE

NDT Technologies (P) Limited

NDT Technologies (P) Limited