Adapt to every shaft alignment challenge

Adapt to the Asset

Adaptive alignment using single-laser technology adapts to virtually all rotating assets, from standard machines (motor pumps) to more complex equipment such as machine trains, gearboxes, Cardan shafts etc.

Adapt to the Situation

With Active Situational Intelligence (ASI) software, adaptive alignment systems automatically adjust to common challenges such as coupling backlash, environmental conditions, and gross misalignments.

Adapt to the Team

Enable less experienced team members to be successful with adaptive alignment tools that adapt to the technician's level of experience, by eliminating user errors and allowing team collaboration through the Cloud.

Unlock your team's potential with adaptive alignment

Adaptive alignment uses single-laser technology and Active Situational Intelligence to adapt to the asset, the situation, and the maintenance team, aligning any rotating asset with new levels of precision and speed.

Maintenance teams can easily handle a wide range of alignment challenges—from simple to complex—avoiding the rework that comes with more basic alignment systems.

Work is completed faster, errors are eliminated, and team capacity is unlocked, enabling maintenance and reliability teams to keep their assets operating at peak efficiency over a longer life.

Speak to an alignment specialistLearn More

Adaptive Alignment Whitepaper

Webinars on demand

Learn from our experts about Adaptive Alignment and find more exclusive webinars on demand in our video library.

Webinars on demandThe power of adaptive alignment

Next-generation shaft alignment technology

Single-laser technology

By the inventor of laser shaft alignment, single-laser technology makes the alignment process

faster and easier to perform compared to basic alignment systems.

Active Situational Intelligence (ASI)

A unique combination of software capabilities that provide real-time,

"in the moment" feedback and guidance, enabling highly precise

measurements even in challenging circumstances.

Cloud Collaboration

Technicians receive alignment tasks from managers and experienced technicians

directly on the device and share measurement results with other team members.

3 facts about single-laser technology

Setting up one laser beam to hit the opposite sensor is much faster than setting up two.

The distance between two machines or the length of the spacer shaft never affects the accuracy of the measurement.

It is always possible to measure, no matter the initial angular misalignment.

Key benefits of adaptive alignment

Unlock team capacity

Adaptive alignment has the intelligence to remove many errors a technician may inadvertently make. It utilizes analytics in real-time, removing erroneous data.

Adaptive systems unlock team capacity: even if an inexperienced technician is doing the alignment, the system corrects common errors to enable the technician to obtain the same high-quality results as a more experienced engineer.

Some adaptive alignment features designed to enhance team performance include:

3-step graphical measurement process wizard guidance: Dimension, Measurement, Results

Users gain instant feedback about measurement quality and while low-quality measurements are automatically filtered out

Share measurement results instantly with maintenance managers and experienced technicians through the Cloud

Automatically identify the machine to be aligned with an integrated RFID tag reader

Extend machine availability (MTBF)

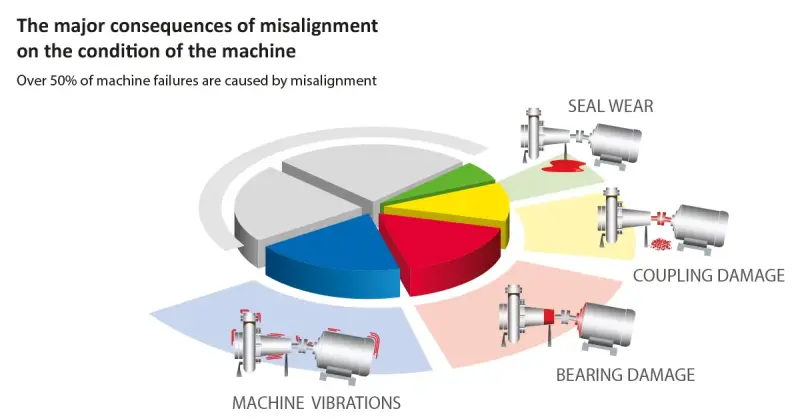

Machine shaft misalignment increases vibration and temperature and accounts for over 50% of machine failures. Aligning the machine into the correct alignment is one of the most effective measures to counteract the effects of misalignment and increase machine availability.

Increasing Mean Time Between Failure (MTBF) can be achieved with precision alignment.

Align simple and complex assets

Adaptive alignment adapts to virtually all rotating assets in your plant, from simple to complex machines.

With the single-laser technology, adaptive systems accelerate simple, daily and, standard alignment tasks. More complex jobs involving challenging machine configurations, gross misalignments, or tight clearances are overcome with far greater ease of use and without having to resort to manual workarounds or time-consuming reworks.

With Active Situational Intelligence (ASI), adaptive alignment systems make complex and challenging tasks easier to handle such as the alignment of Cardan shafts,vertical, flanged machines with right-angle gearboxes, or extensive machine trains with gearboxes. Adaptive features include:

Simultaneous Machine Train Alignment

Total Thermal Coverage

In-Situ Cardan Shaft Alignment

Vertical Alignment

Cut operating and maintenance costs

Precision alignment at installation time is a proactive maintenance technique that ensures high performance, high efficiency, and longer machine life right from the beginning.

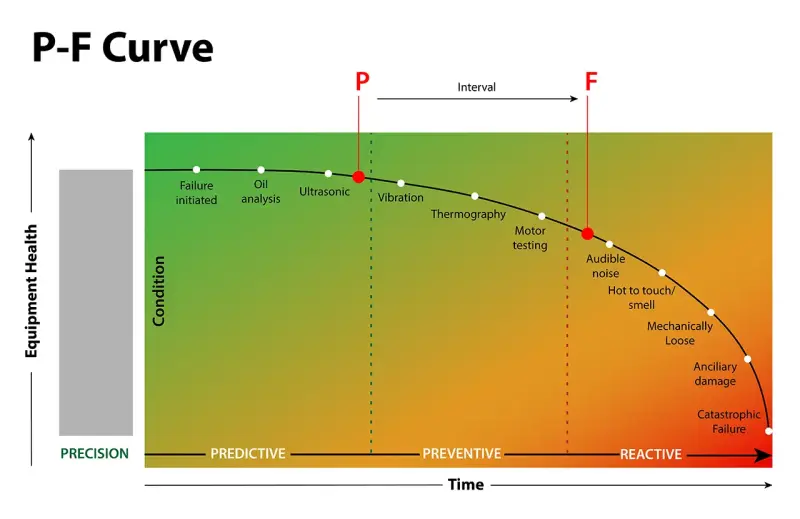

Precision alignment at commissioning and during operation helps lengthen or slow down the P-F curve and avoid rising repair costs as the machine condition deteriorates and eventually fails. During operation, alignment is the first measure to take after a machine was diagnosed with high vibration. In fact, over 50% of machine failure is caused by misalignment.

Adaptive alignment supports a long-term alignment strategy for the entire plant with asset-based data management and archiving in ARC 4.0 software Using ARC 4.0 software, engineers can trend alignment data to perform data-driven root-cause assessments of chronic misalignments.

Optimize Return on Investment (ROI)

Moving the machine is often the costliest part of an alignment, carrying with it the risk of even more cost and time if it turns out to be the wrong move.

The combination of advanced single-laser technology and software intelligence delivers maximum precision and highly reliable results. This is critical to ensure that the machine movements that are about to be carried out are the correct ones and can be performed accurately.

Vertical Move Simulator (MVS) combined with the single-laser has saved technicians thousands of hours across many industries around the world. It enables them to model different options for a move, see the results, and refine choices before actually doing the physical movement.

FAQs

What is adaptive alignment?

Adaptive alignment is the next generation of laser alignment systems – developed by PRUFTECHNIK, the inventors of laser shaft alignment who continue to innovate in the field. It is a combination of software and hardware innovations enabling maintenance teams to address a wide variety of alignment challenges that basic laser alignment systems cannot handle.

Adaptive alignment systems can adjust to:

The asset itself

The alignment situation or challenge

The experience and skill level of the technician and team assigned with completing the alignment task

Adaptive alignment systems eliminate “guesstimates,” wasted effort, and time-consuming rework that occur with basic laser alignment systems.

What products do we have in the adaptive alignment category?

ROTALIGN Touch

ROTALIGN Touch EX

OPTALIGN Touch

SHAFTALIGN Touch

Why do I need an adaptive alignment system?

Because you don’t want to spend good money on an alignment system that either can’t handle all your alignment tasks or can’t grow with your needs. With today’s wide range of asset types, alignment situations, and team skills, you can’t attempt to get by with a basic, limited system. While these systems are sometimes cheaper, they yield false savings. What you might save in the cost of other systems, you will pay many times over in time-consuming rework and lower precision.

What makes adaptive alignment products unique?

Two innovations – Single-Laser Technology and Active Situational Intelligence – differentiate adaptive alignment products from their basic predecessors. Together, they deliver the “magic” that enables PRUFTECHNIK alignment products to automatically adapt – in real time, as alignment jobs are finished – to the asset, the situation, and the technician.

What are the benefits of adaptive alignment?

Besides their ability to handle all alignment tasks, from simple everyday jobs to more complex challenges, adaptive alignment products deliver:

New levels of speed and accuracy

Greater ability to restore assets to peak performance

Support for a broader range of critical rotating asset types

Unlocked team capacity by enabling every technician to work faster, archive highly precise alignment results, and collaborate instantly with experts when necessary

I only have simple, straightforward alignment tasks - why do I need an adaptive alignment system?

With an adaptive alignment system, your team will complete jobs faster and with greater precision – even for everyday alignment tasks. That’s because Active Situational Intelligence (ASI) is always at work, correcting for common human errors and environmental problems without slowing the job down.

Adaptive alignment systems enable you to entrust alignment jobs to technicians with less experience, without compromising the results. ASI is there to help them, and with cloud collaboration, they can share measurements and get advice from more senior technicians without having to leave the asset.

Basic systems do not possess these qualities, and therefore cannot deliver such benefits.

But you also need to consider whether all your alignment tasks are straightforward – and will always be. Often plants have special situations, such as a few unusual machine configurations, gross misalignments, tight clearances, or environmental factors that come into play. In those cases, a basic alignment system runs into difficulties, and the time and cost for the alignment job escalate. Often, what maintenance leaders save with a cheaper system in the short term, they lose in manual efforts and rework over time.

Why is an adaptive alignment system better than other systems?

Adaptive alignment systems enable users to efficiently handle a wide range of alignment challenges – from simple to complex scenarios – avoiding the rework that comes with more basic systems. Furthermore, ease of use is strengthened in the many situations where basic laser alignment systems struggle. Adaptive alignment systems eliminate human error while delivering new levels of accuracy and speed. This next generation in laser shaft alignment is made possible by two must-have underlying innovations: Single-Laser Technology and Active Situational Intelligence.

They work faster, eliminate errors, and unlock team capacity, enabling maintenance and reliability teams to ensure maximum operational life and efficiency for critical assets entrusted to their care.

FAQ Adaptive Alignment

Download more information for free

Recommended products

The ROTALIGN touch with its larger detector, move simulator and ease of use has made the alignments in the Test Cell that much easier. Given the use of turn buckles on the inboard end of the engine for adjustment, the ability in the ROTALIGN touch to show both vertical and horizontal adjustments live at the same time is essential.

PRUFTECHNIK has always been an excellent technology for Condition Monitoring, laser alignment and quality control of rotating equipment.

It is hard not to be happy when you have world’s best alignment tool in your hand.

At our work site we use the ROTALIGN touch laser instrument as a high-end system for shaft pump alignment. The system delivers the best measurement accuracy while offering the most innovative features that save you much time and effort.

I enjoy the method of alignment with ROTALIGN touch. The product is perfect.

The ROTALIGN touch with its larger detector, move simulator and ease of use has made the alignments in the Test Cell that much easier. Given the use of turn buckles on the inboard end of the engine for adjustment, the ability in the ROTALIGN touch to show both vertical and horizontal adjustments live at the same time is essential.

PRUFTECHNIK has always been an excellent technology for Condition Monitoring, laser alignment and quality control of rotating equipment.