Past zich aan aan elke uitlijnuitdaging

Aanpassing aan de Machine

Adaptieve uitlijnsystemen met de Single Laser technologie, passen zich aan aan elke roterende machine: van klassieke machines zoals een motorpomp tot meer complexe installaties zoals machinetreinen, cardanassen en nog veel meer.

Aanpassing aan de Situatie

Adaptieve uitlijnsystemen met de Active Situational Intelligence (ASI) software, passen zich aan aan elke uitlijnuitdaging bv. bij koppelingsspeling, omgevingstrillingen en grote uitlijnfouten

Aanpassing aan het Onderhoudsteam

Adaptieve uitlijnsystemen ondersteunen elke monteur door gebruikersfouten te elimineren, zich aan te passen aan het vaardigheidsniveau van de gebruiker en samenwerking mogelijk te maken dankzij de Cloud-transfer.

Verhoog de teamcapaciteit

Adaptieve uitlijnsystemen gebruiken de Single Laser technologie en Active Situational Intelligence om zich aan te passen aan de machine, de situatie en het onderhoudsteam.

Onderhoudsteams kunnen gemakkelijk een breed scala aan uitlijnuitdagingen aan - van eenvoudige tot de meest complexe scenario's, waarbij extra werk en bijkomende aanpassingen van basissystemen vermeden worden.

Adaptive Alignment werkt sneller, elimineert fouten en vergroot de teamcapaciteit waardoor onderhouds- en betrouwbaarheidsteams een maximale levensduur en efficiëntie kunnen garanderen voor de kritieke activa die aan hun zorg zijn toevertrouwd.

Neem contact op met een specialistMeer info...

Adaptive Alignment Whitepaper

Opgenomen Webinars

Leer van onze experts over Adaptive Alignment en vind meer exclusieve webinars op aanvraag in onze videobibliotheek.

Opgenomen WebinarsDe kracht van Adaptive Alignment

Technologie van de volgende generatie

Single Laser technologie

Ontworpen door de uitvinder van laseroptisch asuilijnen,

maakt de Single Laser technologie het uitlijnproces sneller

en eenvoudiger in vergelijking met basis uitlijnsystemen.

Active Situational Intelligence (ASI)

Een firmware die real time tijdens de job feedback en

begeleiding biedt, waardoor uiterst nauwkeurige metingen

in uitdagende omstandigheden uitgevoerd kunnen worden .

Gegevensoverdracht via de Cloud

Monteurs ontvangen de uitlijntaak van hun managers of

ervaren technici in real time op het uitlijntoestel en kunnen nadien

de meetresultaten meteen delen met andere teamleden.

3 feiten over de Single Laser technologie

Eén laser en één sensor opstellen is veel sneller dan twee van elk.

De meetafstand heeft nooit effect op de meting.

Er kan altijd gemeten worden vanuit eender welke hoekpositie.

Voornaamste voordelen van Adaptive Alignment

Verhoog de teamcapaciteit

Adaptive Alignment heeft de intelligentie om veel fouten te verwijderen die een monteur per ongeluk kan maken. Het systeem maakt gebruik van analyses in real time, waardoor foutieve gegevens verwijderd worden.

Adaptieve systemen verhogen de teamcapaciteit: zelfs als een onervaren monteur de uitlijning uitvoert, corrigeert het systeem veelvoorkomende fouten zodat de monteur dezelfde hoogwaardige resultaten kan behalen als een meer ervaren technieker.

Enkele adaptieve uitlijnfuncties die ontworpen zijn om de teamprestaties te verbeteren zijn:

Met de intuïtieve gebruikersinterface hoeft u slechts drie stappen te volgen: afmetingen invoeren, meten en resultaten evalueren.

De gebruiker krijgt meteen feedback over de meetkwaliteit, irrelevante meetgegevens worden gedetecteerd en automatisch uitgefilterd.

Deel meetresultaten met onderhoudsmanagers en ervaren technici via de Cloud.

Automatische machine-identificatie met de RFID-lezer

Verhoog de standtijd van uw machine (MTBF)

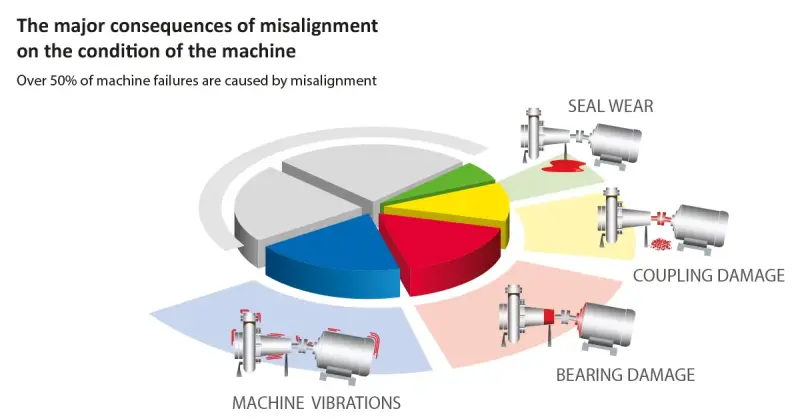

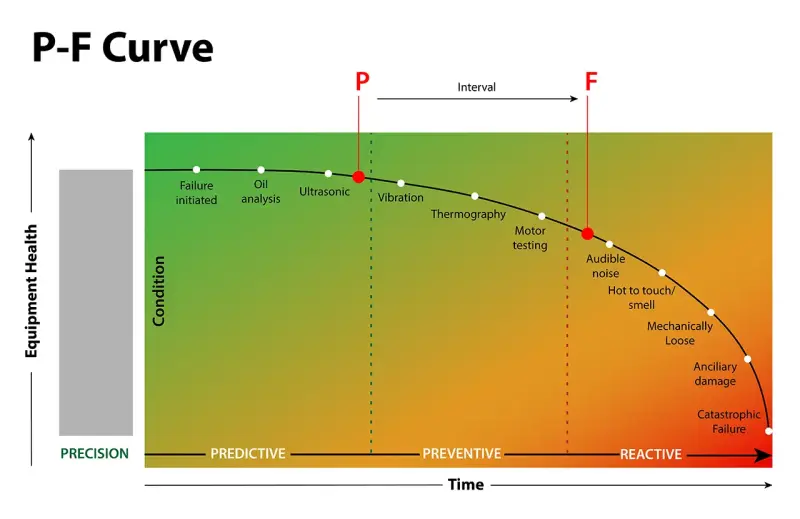

Meer dan 50% van de machinestoringen wordt veroorzaakt door een verkeerde uitlijning. Een correcte uitlijning is één van de belangrijkste factoren om de levensduur van machines te verlengen.

Mean Time Between Failure (MTBF) verlengen, is mogelijk met precisie uitlijnen.

Klassieke en complexe machines uitlijnen

Adaptive Alignment past zich aan aan elke machine, van klassieke tot complexe installaties.

Dankzij de Single Laser technolgie, kunnen adaptieve uitlijnsystemen eender welke uitlijntaak aan, van standaard, dagelijkse en eenvoudige uitlijnopdrachten tot meer complexe en uitdagende taken, zonder toevlucht te moeten nemen tot handmatige workarounds of tijdrovend aanpassingswerk.

Adaptieve uitlijnsystemen met de Active Situational Intelligence (ASI) software, vereenvoudigen complexe en uitdagende uitlijntaken zoals bv. het uitlijnen van cardanassen, verticale machines en nog veel meer. Adaptieve functies omvatten:

Simultaneous Machine Train Alignment

Total Thermal Coverage

In-Situ Cardan Shaft Alignment

Vertical Alignment

Bespaar tijd en onderhoudskosten

Een nauwkeurige uitlijning tijdens de installatie is een proactieve onderhoudstechniek, die van in het begin hogere prestaties, een hogere efficiëntie en een langere levensduur garandeert.

Tijdens productie is de uitlijncontrole een van de eerste maatregelen die moet worden genomen nadat bij een machine een hoge trilling vastgesteld werd. In feite wordt meer dan 50% van de machinestoringen veroorzaakt door een verkeerde uitlijning.

Adaptieve systemen met op het machinepark afgestemde uitlijnsoftware volgen de uitlijnconditie in de loop van de tijd op in ARC 4.0, en ondersteunen zo de lange termijn strategie van de volledige fabriek. Dankzij de ARC software, kunnen de engineers de uitlijngegevens analyseren om terugkerende uitlijnfouten te diagnosticeren.

Optimize Return on Investment (ROI)

Het verplaatsen van de machine is vaak het duurste onderdeel van de uitlijning en brengt het risico met zich mee van nog meer kosten en tijd, als blijkt dat het een verkeerde zet is.

De combinatie van de Single Laser technologie en de intelligente software zorgt voor nog nauwkeurigere metingen en uiterst betrouwbare resultaten. Dit is cruciaal om te kunnen verzekeren dat de machineverplaatsing die uitgevoerd dient te worden, de juiste is.

Vertical Move Simulator (VMS) in combinatie met de Single Laser technologie heeft monteurs reeds duizenden uren bespaard in vele industrieën over de hele wereld. Het stelt hen in staat om verschillende opties voor een beweging te modelleren, de resultaten te bekijken en keuzes te verfijnen voordat ze daadwerkelijk de fysieke beweging uitvoeren.

FAQs

What is adaptive alignment?

Adaptive alignment is the next generation of laser alignment systems – developed by PRUFTECHNIK, the inventors of laser shaft alignment who continue to innovate in the field. It is a combination of software and hardware innovations enabling maintenance teams to address a wide variety of alignment challenges that basic laser alignment systems cannot handle.

Adaptive alignment systems can adjust to:

The asset itself

The alignment situation or challenge

The experience and skill level of the technician and team assigned with completing the alignment task

Adaptive alignment systems eliminate “guesstimates,” wasted effort, and time-consuming rework that occur with basic laser alignment systems.

What products do we have in the adaptive alignment category?

ROTALIGN Touch

ROTALIGN Touch EX

OPTALIGN Touch

SHAFTALIGN Touch

Why do I need an adaptive alignment system?

Because you don’t want to spend good money on an alignment system that either can’t handle all your alignment tasks or can’t grow with your needs. With today’s wide range of asset types, alignment situations, and team skills, you can’t attempt to get by with a basic, limited system. While these systems are sometimes cheaper, they yield false savings. What you might save in the cost of other systems, you will pay many times over in time-consuming rework and lower precision.

What makes adaptive alignment products unique?

Two innovations – Single-Laser Technology and Active Situational Intelligence – differentiate adaptive alignment products from their basic predecessors. Together, they deliver the “magic” that enables PRUFTECHNIK alignment products to automatically adapt – in real time, as alignment jobs are finished – to the asset, the situation, and the technician.

What are the benefits of adaptive alignment?

Besides their ability to handle all alignment tasks, from simple everyday jobs to more complex challenges, adaptive alignment products deliver:

New levels of speed and accuracy

Greater ability to restore assets to peak performance

Support for a broader range of critical rotating asset types

Unlocked team capacity by enabling every technician to work faster, archive highly precise alignment results, and collaborate instantly with experts when necessary

I only have simple, straightforward alignment tasks - why do I need an adaptive alignment system?

With an adaptive alignment system, your team will complete jobs faster and with greater precision – even for everyday alignment tasks. That’s because Active Situational Intelligence (ASI) is always at work, correcting for common human errors and environmental problems without slowing the job down.

Adaptive alignment systems enable you to entrust alignment jobs to technicians with less experience, without compromising the results. ASI is there to help them, and with cloud collaboration, they can share measurements and get advice from more senior technicians without having to leave the asset.

Basic systems do not possess these qualities, and therefore cannot deliver such benefits.

But you also need to consider whether all your alignment tasks are straightforward – and will always be. Often plants have special situations, such as a few unusual machine configurations, gross misalignments, tight clearances, or environmental factors that come into play. In those cases, a basic alignment system runs into difficulties, and the time and cost for the alignment job escalate. Often, what maintenance leaders save with a cheaper system in the short term, they lose in manual efforts and rework over time.

Why is an adaptive alignment system better than other systems?

Adaptive alignment systems enable users to efficiently handle a wide range of alignment challenges – from simple to complex scenarios – avoiding the rework that comes with more basic systems. Furthermore, ease of use is strengthened in the many situations where basic laser alignment systems struggle. Adaptive alignment systems eliminate human error while delivering new levels of accuracy and speed. This next generation in laser shaft alignment is made possible by two must-have underlying innovations: Single-Laser Technology and Active Situational Intelligence.

They work faster, eliminate errors, and unlock team capacity, enabling maintenance and reliability teams to ensure maximum operational life and efficiency for critical assets entrusted to their care.

FAQ Adaptive Alignment

Download more information for free

Download vrijblijvend

Aanbevolen producten

ROTALIGN touch

Kom meer te wetenOPTALIGN touch

Kom meer te wetenSHAFTALIGN Touch

Kom meer te wetenPRUFTECHNIK is altijd een uitstekende technologie voor conditiebewaking, laseruitlijning en kwaliteitscontrole van draaiende apparatuur.

Het is moeilijk om niet gelukkig te zijn als je de beste tool voor uitlijning ter wereld in handen hebt!

We hebben de ROTALIGN touch lasermachine op de werkplek gebruikt als een high-end systeem voor het uitlijnen van de aspomp. Het systeem levert de beste meetnauwkeurigheid en biedt de meest innovatieve functies die u veel tijd en moeite besparen.

Ik ben blij met de uitlijningsmethode van ROTALIGN touch. Het product is perfect.