Geometrical Measurement Software

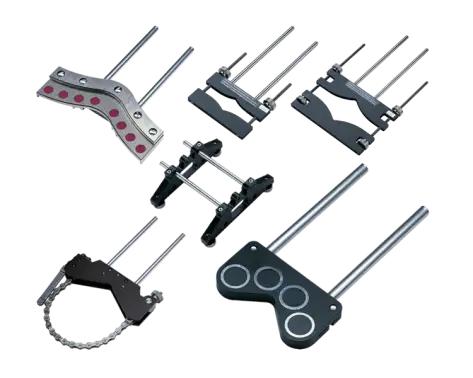

Activate your machinery more quickly, and help it run longer. PRÜFTECHNIK geometric laser alignment tools and software enable you to easily check and adjust your machine geometries for: straightness, flatness, level, inclination, plumbness, parallelism, and right angle check. Our tools are powerful, precise, and easy to use on a vast range of machinery—they can measure for the most demanding alignment jobs, including a bore of almost any diameter, and/or any surface type or inclination. Find the right geometric measurement tool for your machines.

Frequently Asked Questions

Geometric measure theory (GMT) studies the geometric properties of sets through what mathematicians call measure theory. GMT lets mathematicians expand the tools provided by differential geometry to cover a much larger class of surfaces, including inclination, straightness, level, and flatness.

What are the Benefits of Using a Geometric Tool?

The Benefits of Geometric Tools

What Geometric Tools Can Help with Geometric Measurement?

Why Surface Flatness and Level are Critical to Laser Shaft Alignment?

What Tools are Used When Making a Geometric Measurement?

Training

We offer alignment, vibration & balancing, ultrasound, and reliability training.

Find a course

Fortive MENA

Fortive MENA