EDDY CURRENT TESTING

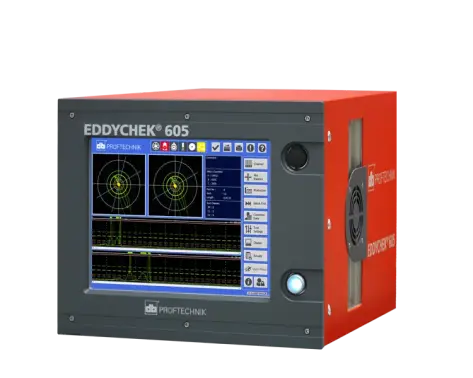

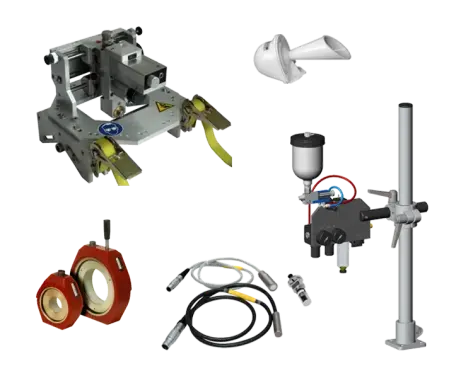

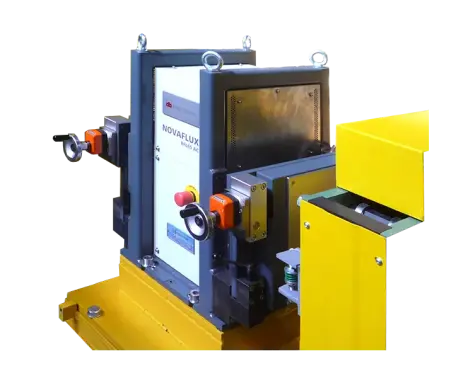

Nondestructive testing systems from PRÜFTECHNIK ensure that manufacturers of semi-finished products and their customers obtain the best possible quality. Our eddy current testing systems and sensors provide quality assurance and process control both during and after production, generating valuable feedback on the production process and ensuring high-quality product.

EDDY CURRENT TESTING FAQ

An eddy current is a current initiated in a conductor that reacts to a changing magnetic field. Eddy currents flow in closed loops within conductors, in planes perpendicular to the magnetic field, and take the form of eddies such as those that occur in whirlpools. They are used widely in several industries, including manufacturing and aerospace where eddy current inspections are required to reduce safety-related or quality-related problems, such as in thin metal areas.

PRUFTECHNIK Inc.

PRUFTECHNIK Inc.